Tailored thermal

hydrolysis solutions

that meet your plant’s

unique needs

At Cambi, we believe in solutions that fit you, not the other way around. Our thermal hydrolysis systems are customisable, modular, reliable, and low-maintenance, ensuring long-term satisfaction with diverse sludge feedstocks.

Thermal hydrolysis

configurations for every plant

Before, after, or as an intermediate step of anaerobic digestion? Choose a configuration best suited to your plant's size, needs, and capacity.

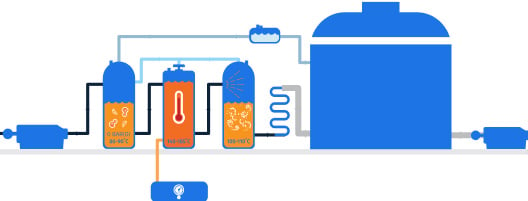

01

THP before

anaerobic digestion

Thermal hydrolysis before anaerobic digestion involves dewatering sludge, heating it in reactors to sterilise and break down organic matter, and then cooling it for anaerobic digestion, resulting in high-quality, land-applicable biosolids.

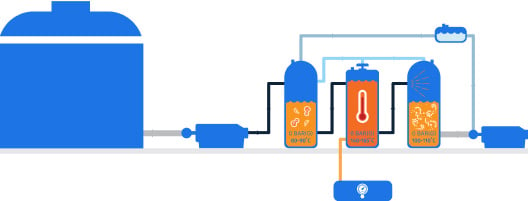

02

THP after

anaerobic digestion

Thermal hydrolysis after anaerobic digestion involves dewatering digested sludge, heating it to sterilise and break down cells, and then further dewatering and cooling it, with the centrate returned to the digester for more biogas production.

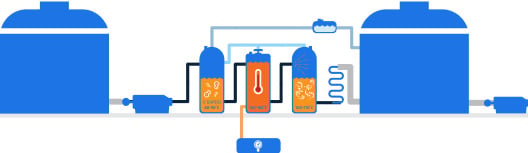

03

THP between

digesters

Thermal hydrolysis between digesters involves pre-dewatering sludge, heating it with steam, sterilising and hydrolysing it under pressure, and then cooling it before feeding it into a second-stage anaerobic digester, resulting in pathogen-free, high-quality biosolids.

Learn what makes them

the best choice for you

Save on investments in brownfield expansions, digester renewals, and new projects

Thermal hydrolysis before anaerobic digestion involves dewatering sludge, heating it in reactors to sterilise and break down organic matter, and then cooling it for anaerobic digestion, resulting in high-quality, land-applicable biosolids.

Increase the performance of projects with high disposal cost and high value of energy.

Achieve sterilised, odour-free sludge cake and reduce sludge volume by up to 60%. Boost biogas production by 25-40%, attain up to 40% dry solids in final biosolids, and enjoy up to 75% volatile solids reduction. Maximise your plant's efficiency and sustainability.

Boost the effects of pre-AD THP without needing abundant digestion capacity

Harness the benefits of this mid-way configuration: enjoy more biogas and better biosolids reduction than pre-digestion THP while needing less digestion capacity than post-digestion THP. Produce pathogen-free, low-odour biosolids while achieving higher dry solids content.

See our complete product portfolio

Cambi offers standardised thermal hydrolysis systems for various capacities, from 1,500 to 32,000 metric tons of dry solids annually. The products are named by reactor volume in cubic meters: B2, B4, B6, and B12. Each system typically uses 2-4 reactors for continuous operation.

CambiTHP B2

The B2 thermal hydrolysis model is CambiTHP's smallest model, perfect for medium-sized wastewater treatment plants. Delivered fully assembled on a single skid with up to 4 reactors, the B2 is a plug-and-play system, designed to simplify and speed up installation and start-up.

.png?width=358&height=356&name=svgviewer-png-output%20(1).png)

CambiTHP B4

The B4 model is ideal for medium to large wastewater treatment plants. It comes as a pre-assembled, tested unit, simplifying and speeding up on-site installation. For greater capacity or backup, multiple B4 units can be installed side by side.

.png?width=358&height=356&name=svgviewer-png-output%20(1).png)

CambiTHP B6

The B6 model best serves medium to large wastewater treatment plants. It comes as a pre-assembled, tested package, making installation and startup quicker and easier. For greater capacity or backup, multiple units can be installed side by side.

.png?width=358&height=356&name=svgviewer-png-output%20(1).png)

CambiTHP B12

The B12 is Cambi's largest thermal hydrolysis model, perfect for large to very large wastewater plants. Its standardised design speeds up on-site installation.

.png?width=358&height=356&name=svgviewer-png-output%20(1).png)

-1.webp?length=1920&name=green-tea-plantations-in-india-2023-11-27-05-07-30-utc%202%20(2)-1.webp)

You are not alone!

From business case to ongoing improvement, we guide you towards more efficient, less wasteful plants. Whether you're a current user or considering our solutions, our experts are here to maximise your plant's potential with thermal hydrolysis and smart integration. Discover what we can do for you!

Ready to transform your waste?

Leave your details below. Our team will reach out promptly to discuss your needs and explain how our innovative thermal hydrolysis solutions can revolutionise your approach to sewage sludge and organic waste management.