Thermal hydrolysis

Increase digester throughput, boost biogas production, and minimise waste while reducing operational costs.

What is the thermal

hydrolysis process?

Before wastewater returns to nature, it undergoes several treatment steps to remove organic matter, nutrients, and pollutants. The remaining solids, called sewage sludge, can be processed in an anaerobic digester to stabilise them and produce biogas. By exposing sewage sludge or other types of wet organic waste to high temperature and pressure, the thermal hydrolysis process (THP) simplifies the sludge breakdown before or after anaerobic digestion.

How does thermal

hydrolysis work?

Think of it like cooking with a pressure cooker.

Thermal hydrolysis subjects sewage sludge or wet organic waste to high temperatures and pressure. This makes the waste easier to break down.

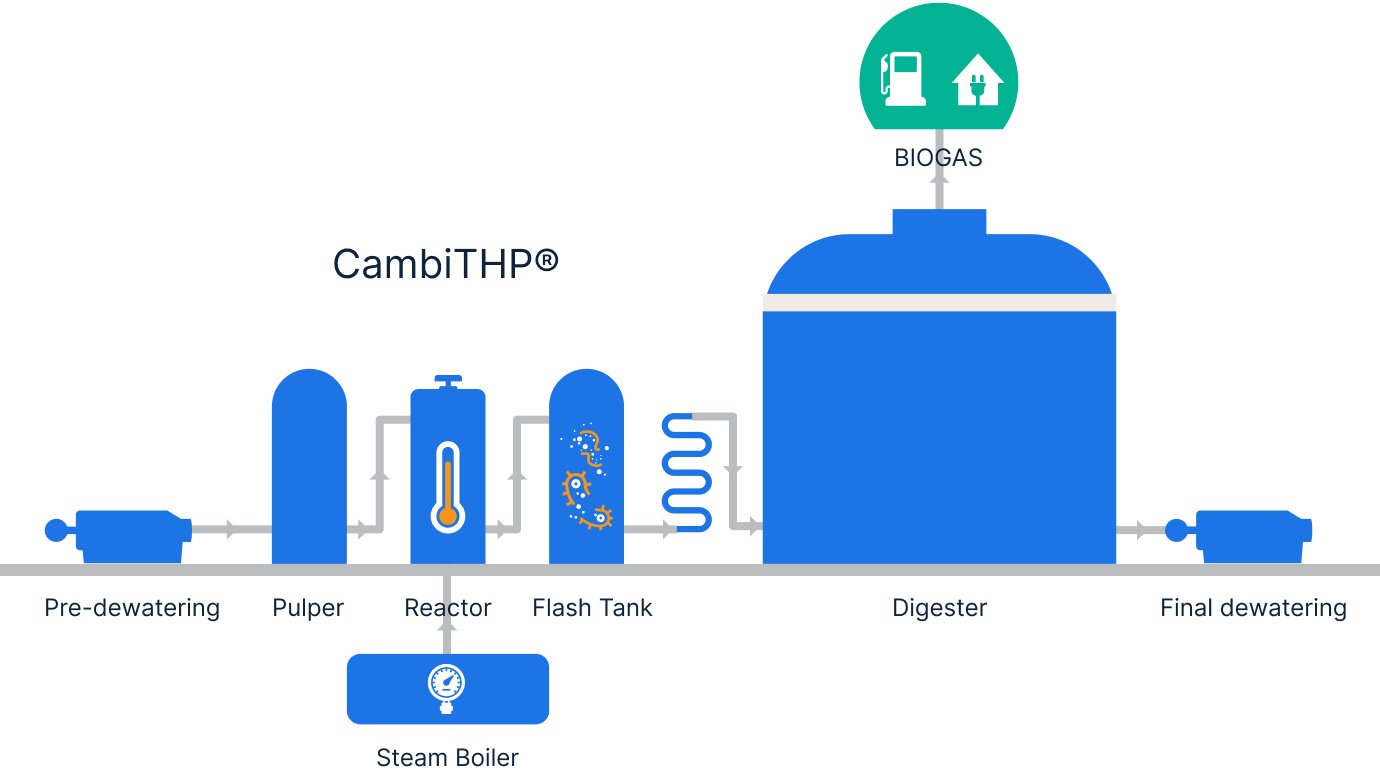

Raw sewage sludge is collected from the primary and secondary treatment units. It is then dewatered to 16-18% dry solids.

This thickened sludge is continuously fed into the pulper. The pulper homogenises and pre-heats the sludge to about 100°C. It uses steam recovered from the flash tank for heating.

From the pulper, warm sludge continuously is fed continuously to the reactors. When one reactor is full, sludge flows to the next available. Usually, there are 2 and 5 reactors in a Cambi thermal hydrolysis train, depending on sludge volume, reactor size and hydraulic retention time.

Once the reactor is full and sealed, steam heats the contents to 160-180°C at a pressure of about 6 bars. The thermal hydrolysis process is typically set at 20-30 minutes per batch. This ensures all pathogens are killed.

From the reactor, the sterilised sludge moves to the flash tank, which operates at atmospheric pressure. The sudden pressure drop leads to substantial cell destruction for the organic matter.The steam generated by the pressure release preheats incoming sludge in the pulper.

After leaving the flash tank, the sludge is cooled in heat exchangers to the temperature needed for anaerobic digestion. Then, it goes into the anaerobic digesters.

Where does thermal hydrolysis fit?

Wastewater is treated in steps, in line with local regulations, to remove organic matter, nutrients, and pollutants. First, inorganic materials are removed, creating primary sludge. Then, secondary sludge with high organic content is separated.

Sometimes, food waste or dewatered sludge from other places is mixed with the on-site sludge.

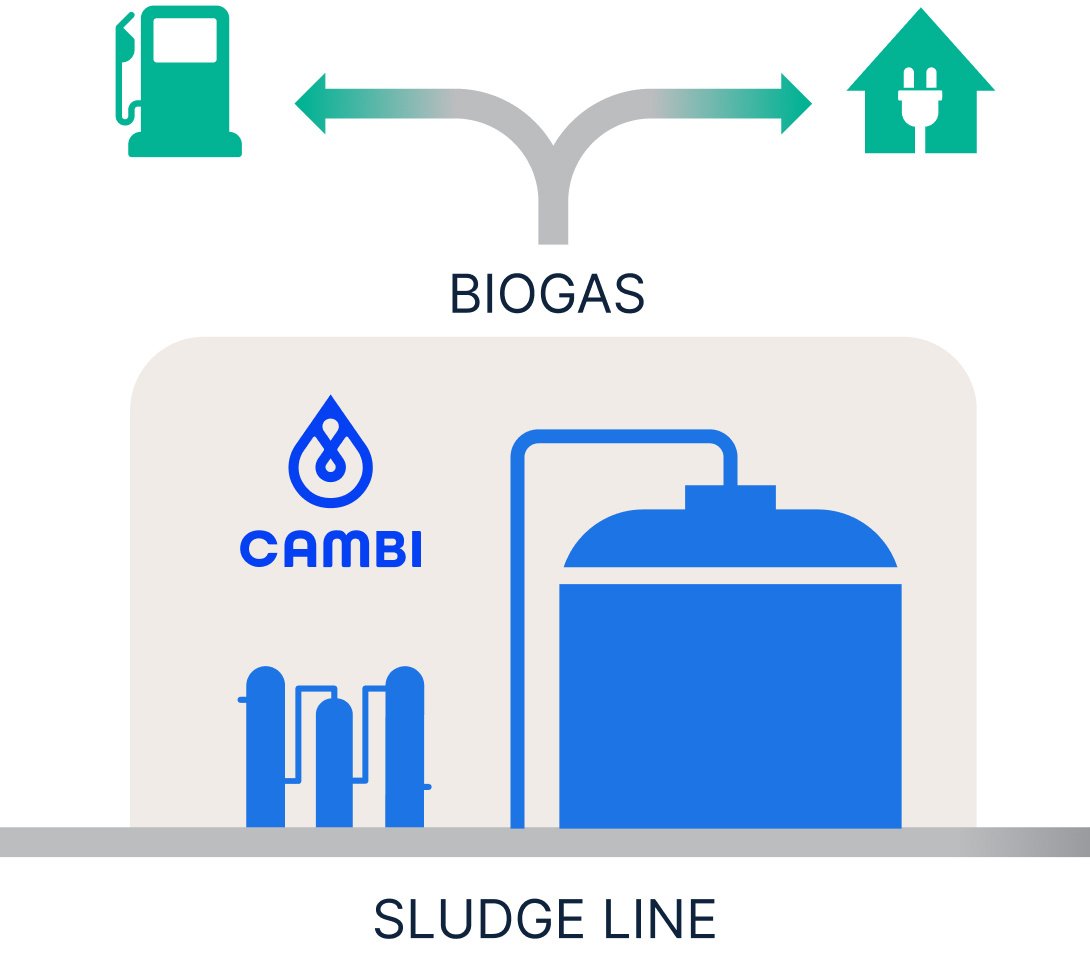

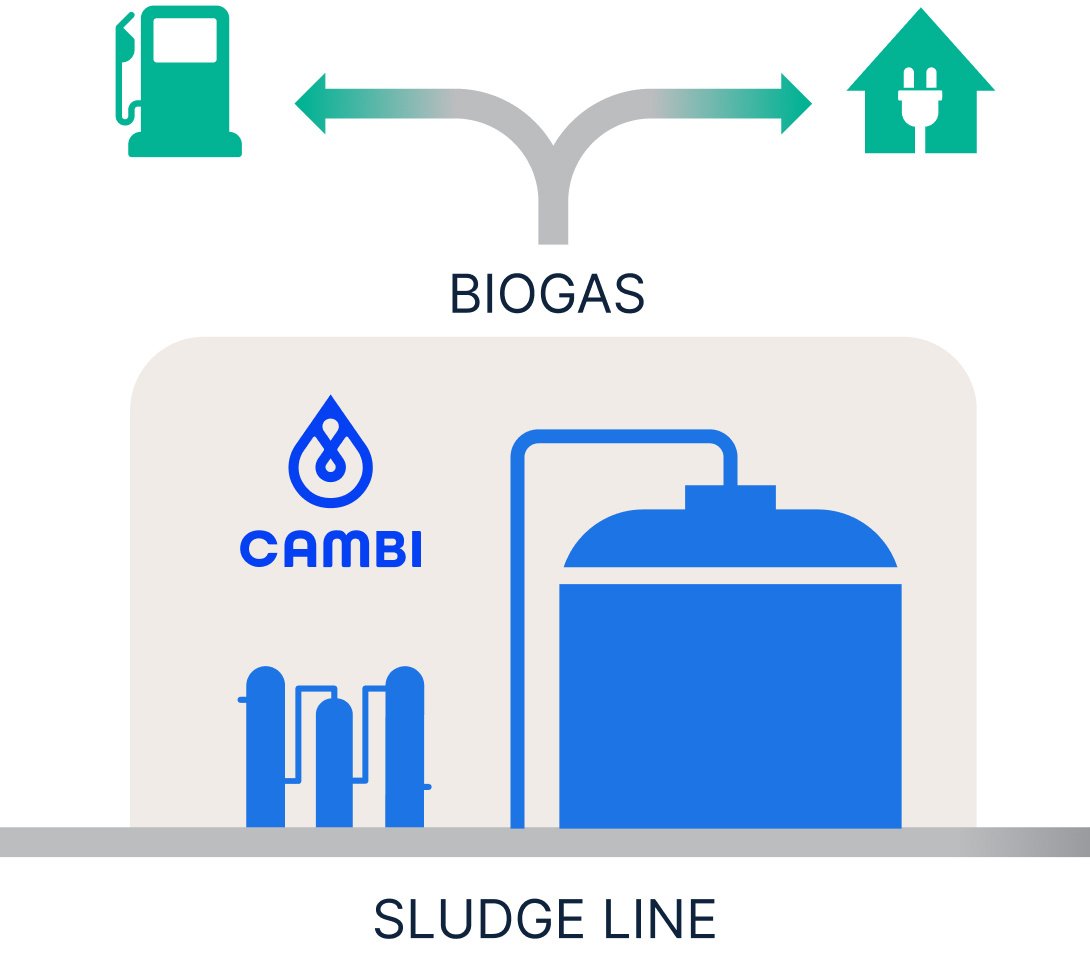

A sludge line includes all the steps a wastewater plant uses to process sludge. This can involve different technologies for recovering energy, reducing smells, destroying pathogens, and meeting legal standards.

Most medium—to large-scale plants recover energy from the sludge via anaerobic digestion. The resulting biogas is then used locally at the plant or sold as electricity or natural gas.

The sludge line design and sludge management practices often have a considerable impact on water utility balance sheets. Cambi makes a difference by optimally integrating our proven thermal hydrolysis process into any sludge line.

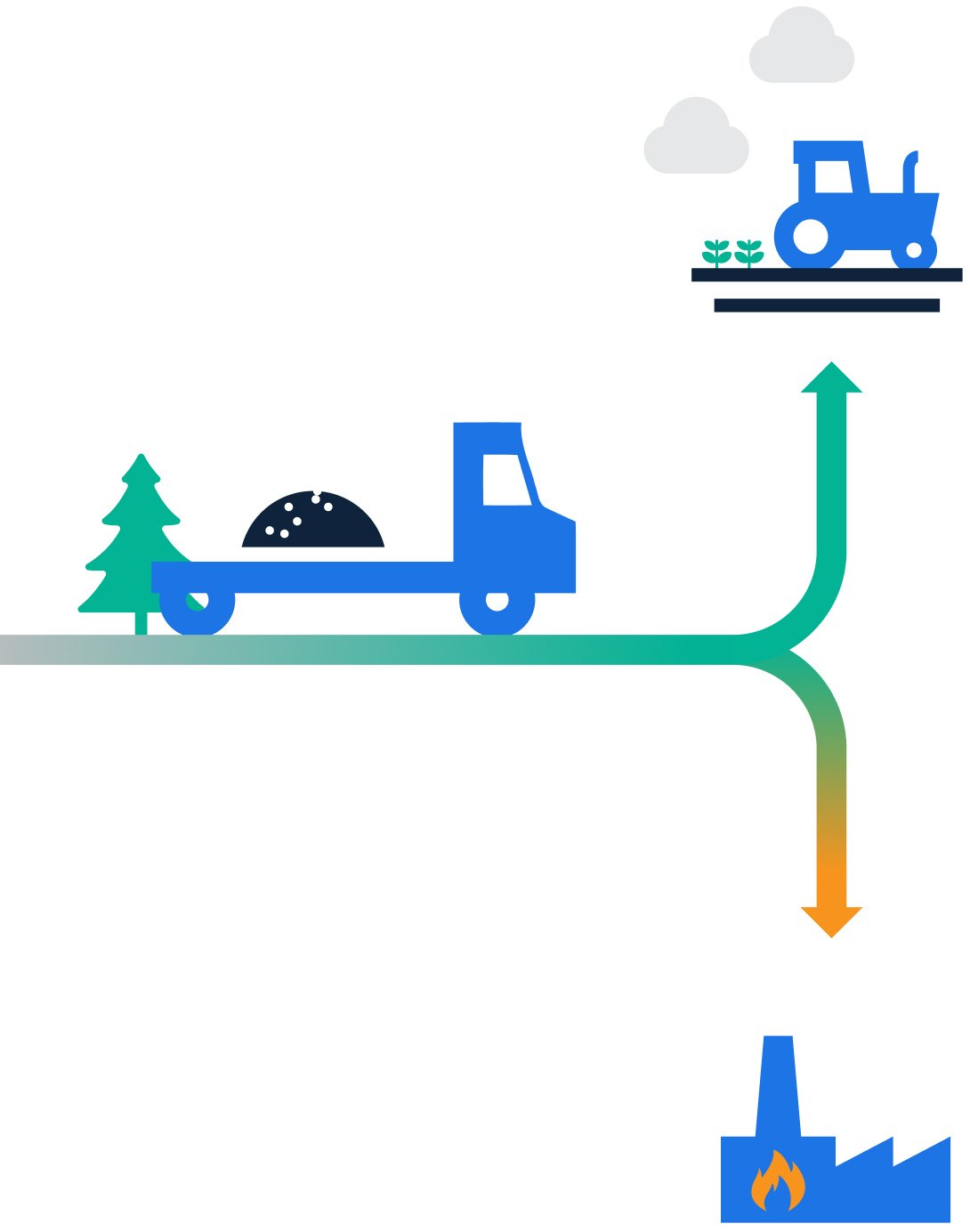

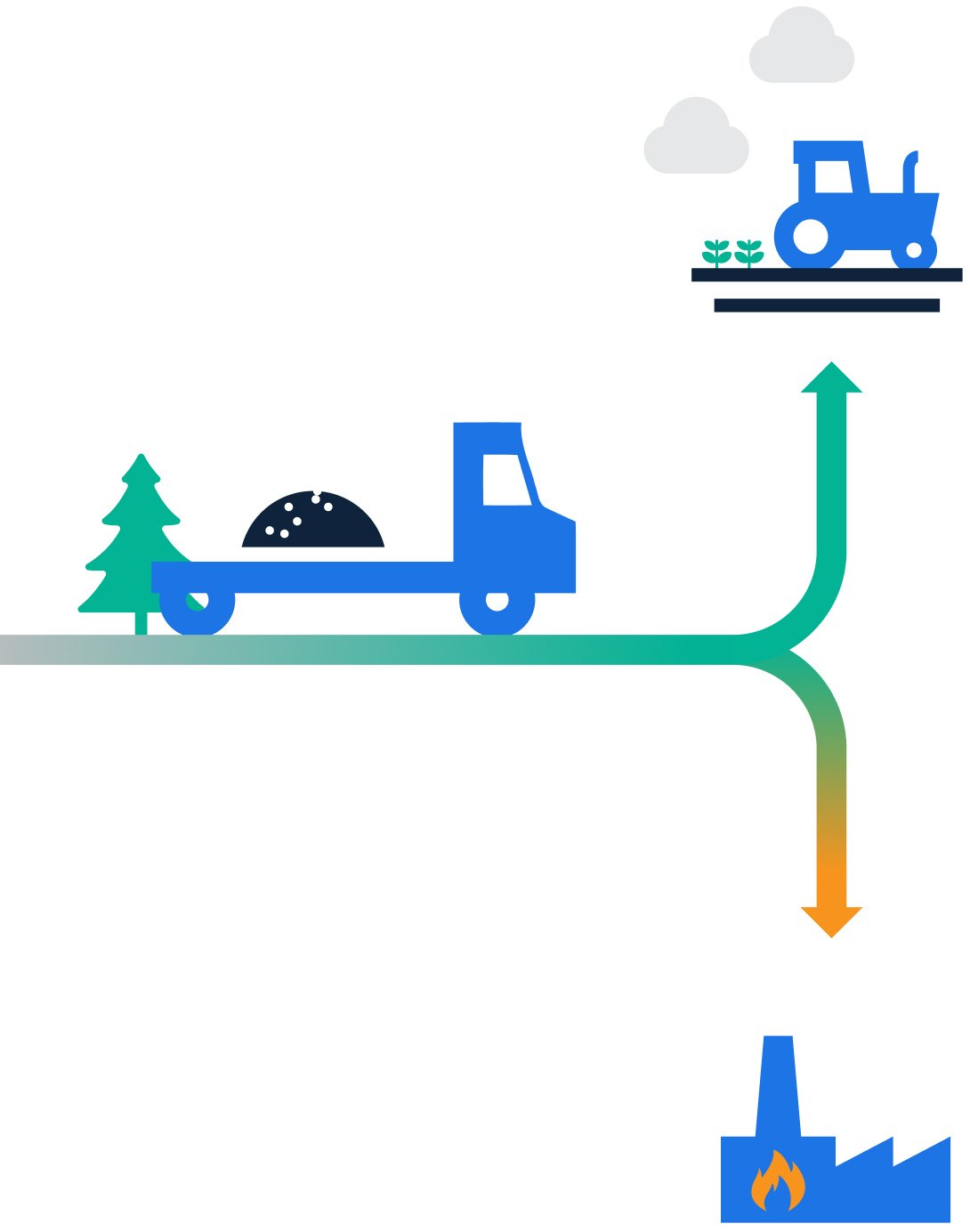

After anaerobic digestion, the sludge is dewatered before final disposal or utilisation. Thermal hydrolysis simplifies sludge management and disposal in several ways:

- It increases biogas production, leaving less digestate behind.

- It makes the final dewatering step use less energy.

- It significantly reduces the volume of biosolids, cutting down handling costs.

- The treated biosolids are pathogen-free, low in odor, and easier to store and transport.

By investing in thermal hydrolysis, water utilities often gain new options for sludge biosolids disposal, such as delivering it to farmers for agriculture.

In areas where incineration is required, the resulting biosolids product has higher calorific value, which may translate into lower gate fees.

Why thermal hydrolysis is

a better way

Thermal hydrolysis increases biogas production while producing pathogen-free biosolids in much smaller amounts than traditional methods. These biosolids are safe for land application and can be used in thermal processes like drying, pyrolysis, and incineration.

Up to 50% higher biogas production

Thermal hydrolysis exposes sewage sludge to high temperature and pressure and then breaks the cell walls to increase biogas production by up to 50% during mesophilic anaerobic digestion. The additional biogas can be used for steam production, to generate green electricity, or as replacement for natural gas, including to fuel vehicles.

Improved biosolids dewatering

Thermal hydrolysis cuts sludge disposal costs by reducing sludge volume. It converts more organic matter to biogas and boosts dewatering efficiency. Less sludge means lower transport and handling costs. Sterilised biosolids are easier to store and handle, and can be used as fertiliser.

High-quality biosolids

High-temperature and pressure sterilisation, followed by steam explosion, destroys pathogens and odorous bacteria after digestion. The resulting Class A biosolids are without pathogen regrowth, low-odour, and meet strict regulations, benefiting both treatment plant workers and nearby communities.

Tripling digester throughput

When thermal hydrolysis pre-treats sewage sludge, it speeds up the hydrolysis step of the anaerobic digestion process. This boosts digester loading rates and reduces hydraulic retention times, tripling throughput. It minimises the size of new digestion plants and maximises the use of existing ones, optimising assets for all projects.

Lower carbon footprint

Cambi thermal hydrolysis offers the lowest carbon footprint for all biosolids outlets by enabling smaller facilities with lower embodied carbon, producing lower volumes of final biosolids, using less energy for thermal processing, generating more renewable energy, and providing new disposal routes.

Built to last, easy

to install

Cambi systems are robust, reliable, and designed for maximum availability. The pre-assembled B2 and B6 systems simplify installation and start-up, saving time and effort on site.

Upgrade your plant!

Find answers to all your questions about thermal hydrolysis. Talk to our experts and turn waste challenges into sustainable solutions.

Learn more about

thermal hydrolysis

Not ready to decide yet? Visit our rich library of resources to find out more about the thermal hydrolysis process and its applications. We also recommend checking out the benefits of various THP configurations to determine what's a potentially good fit for your plant.

Ready to transform your waste?

Leave your details below. Our team will reach out promptly to discuss your needs and explain how our innovative thermal hydrolysis solutions can revolutionize your approach to sewage sludge and organic waste management.